Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

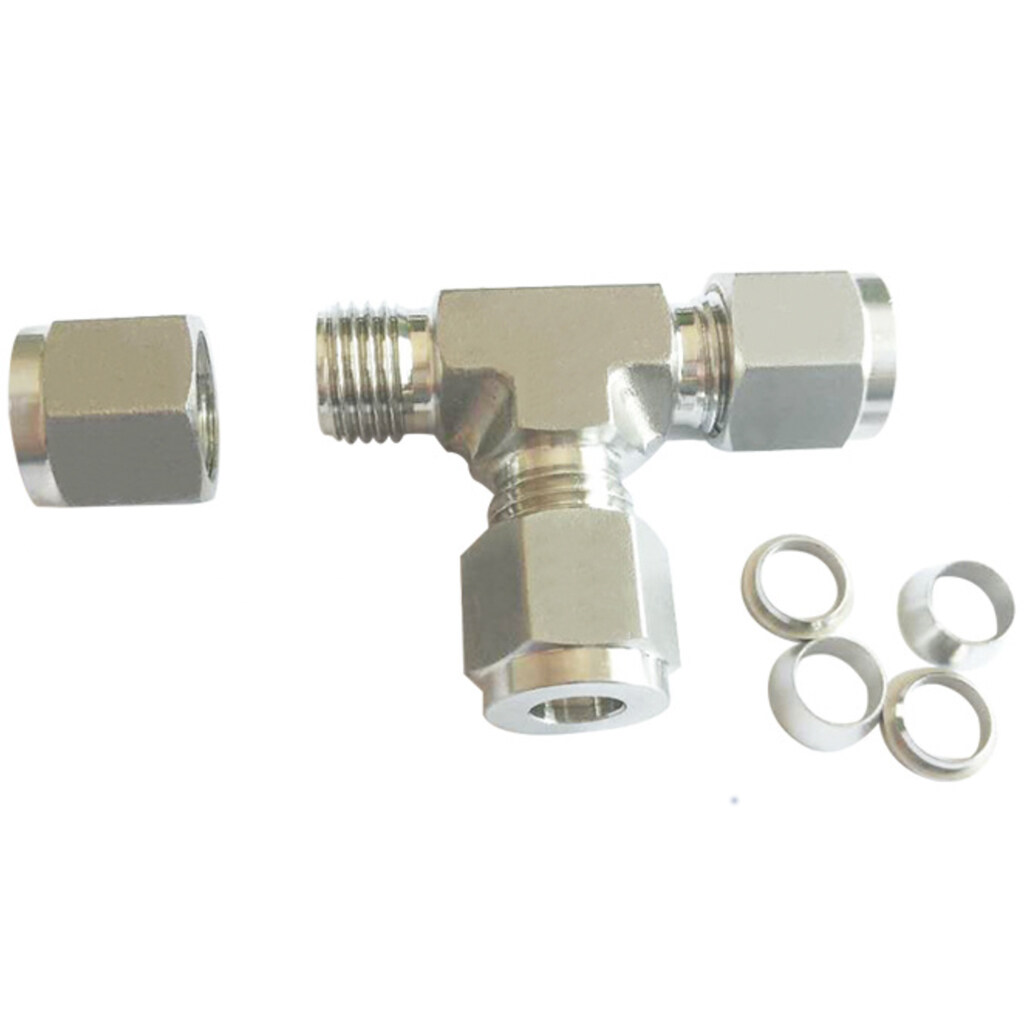

Three-way hydraulic compression pipe joint

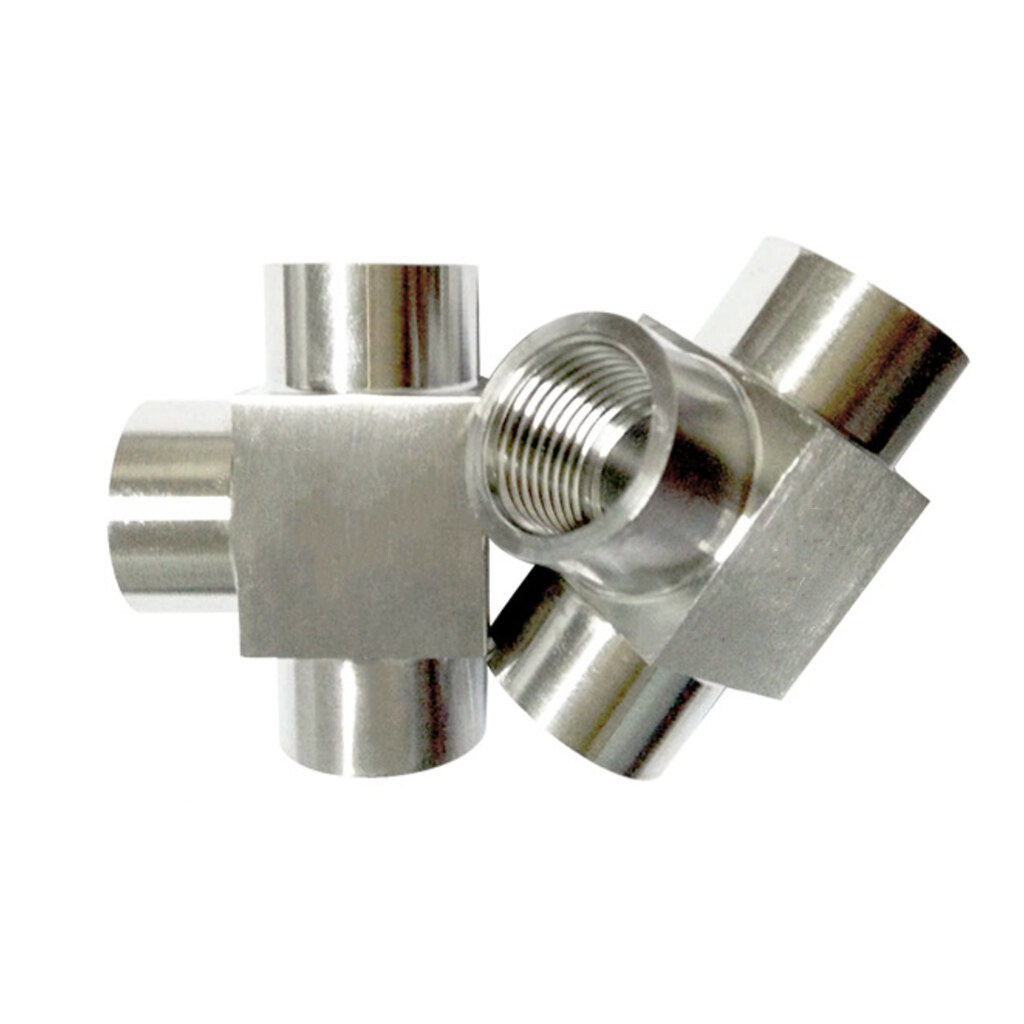

The component that joins the high-pressure oil pipe and the high-pressure oil pipe in the hydraulic system is known as the hydraulic pipe joint. High pressure ball valves, tube joints, welded pipe joints, high pressure hoses, transition pipe joints, tee pipe joints, non-standard pipe joints, expansion pipe hole type pipe joints, right-angle fittings, swivel fittings, quick connectors, stainless steel fittings, and copper fittings are some of the different types of hydraulic pipe joints.

Three-Way Hydraulic Compression Pipe Joint

The hydraulic pipe joint is the part that connects the high-pressure oil pipe and the high-pressure oil pipe in the hydraulic system. Hydraulic pipe joints can be divided into hydraulic hoses, high pressure ball valves, quick connectors, tube joints, welded pipe joints, high pressure hoses, transition pipe joints, tee pipe joints, non-standard pipe joints, expansion pipe hole type pipe joints, Right-angle fittings, swivel fittings, quick connectors, stainless steel fittings, copper fittings.

The cleaning of Three-Way Hydraulic Compression Pipe Joint

The cleaning of hydraulic pipe joints is divided into two types: kerosene cleaning and pickling.

Kerosene cleaning objects and methods

(1) copper pipe, stainless steel pipe;

(2) Steel pipes that have been pickled before pre-installation and have no rust or scale on the inner wall;

(3) Dirty pipe joints during pre-installation;

(4) Remove the pipes and joints that need to be cleaned, wipe the inside of the pipes with a cloth dipped in kerosene, soak both ends and joints in kerosene to clean, then coat the pipes with engine oil or fill them with grease, and seal the two ends for installation;

(5) After cleaning, there should be no visible pollutants, and special attention should be paid to cleaning the welding slag on the inner wall of the welding place.

Pickling objects and methods

(1) Steel pipes that have not been pickled before pre-installation;

(2) Steel pipes that have been pickled but severely corroded.

(3) Use a degreasing agent to remove the grease adhering to the piping;

(4) Remove the dirt on the pipe with clean water;

(5) Remove rust spots, rolling iron filings, etc. on the pipe wall in the pickling solution;

(6) Rinse the attachments produced in the above operations with clean water, and rinse the inside of the pipe with high-pressure water;

(7) Neutralize the residual acid on the pipe with lye;

(8) In order to dry effectively, the pipe should be soaked in hot water or steam dried, and the pipe should be completely dried;

(9) Anti-rust;

(10) Check the pickled pipes to see if they are cleaned;

(11) Immediately after pickling, seal the opening of the tube with plastic or plastic tape to prevent the intrusion of foreign matter and water.